-

Welding Machine for the Making of Metal Cans Pails Buckets Barrels and Drums

This FH18-90ZD-25 is for metal pail making industry, Metal Pail Bucket Drum Body Welder, Paint Tin Can Pail Bucket Drum Making Machine, the diameter range is φ250-350mm(10 to 13 3/4 inches). Height range 260-550mm(10 1/4 to 21 1/2 inches). It is fine with general 5-gallon metal pail making.

-

30L-50L large barrel round metal can oil barrel beer barrel can seam welding machine

To find large barrel round metal can oil barrel beer barrel can seam welding machine, get to know the price of metal can making machine, custom metal can produccing line, Tin Can making Machine supplier Chengdu Changtai Can Manufacture Equipment Co.,ltd

To learn more about this 30L-50L can seam welding machine, please check the details below!

-

Can making machine powder system for metal can round can square can

The consumption of compressed air is very low, only for pneumatic control, the maximum is 150L.

-

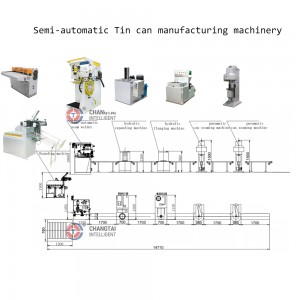

10-20L semi-automatic square can production line

The can body can be square shaped.The can making production line is suitable for the semi-automatic production of 10-20L square can, which is composed of three metal plates: can body, can cover and can bottom.

-

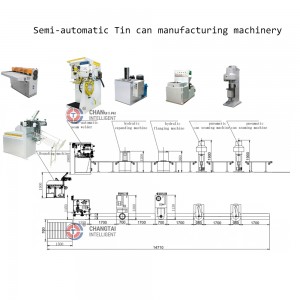

10-25L semi-automatic conical round can production line

The can making production line is suitable for the semi-automatic production of 10-25L conical pail.

-

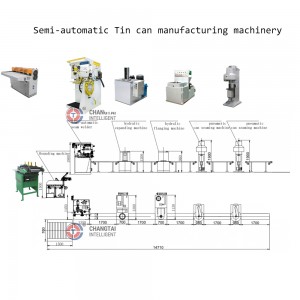

30-50L semi-automatic large barrel can production line

Changtai is expertise in making Semi-automatic Round,square,rectangular Can Making Machinery and easy handle food Tin Can Making Production Line, which is composed of three metal plates: can body, can cover and can bottom. The can body can be square shaped.The can making production line is suitable for the semi-automatic production of 30-50L large barrel.

-

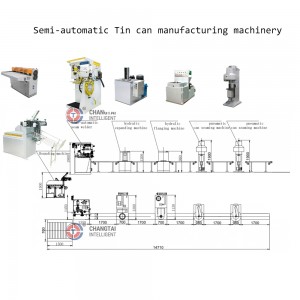

0.1-5L semi-automatic round can production line

Changtai is expertise in making Semi-automatic Round,square,rectangular Can Making Machinery and easy handle food Tin Can Making Production Line, which is composed of three metal plates: can body, can cover and can bottom. The can making production line is suitable for the semi-automatic production of 0.1-5L round can.

-

Can making machine leak hunting machine for metal can round can square can

Aerosol Can Testing Machine for Can Making

Non destructive testing;

Temperature compensation system, improve the detection accuracy.

Equipment interface humanization, easy operation.

Fast changeover and height adjustment

Using European brand sensors to ensure high accuracy of test results, and customized PLC system can save the test results. -

Automatic 0.1-5L round can production line

The can making production line is suitable for the automatic production of 0.1-5L round can, which is composed of three metal plates: can body, can cover and can bottom. The can body is round.

Technical flow:cutting the tin sheet to blank-rounding-welding-outer coating-flanging-bottom lid feeding-seaming-turning over-top lid feeding-seaming-+ear lug welding-leak testing-packaging -

1L-10L tin can making machine metal food cans semi-automatic can welding machine

Can Body Welding Machines

-

10L-25L tin can making machine metal food cans semi-automatic can welding machine

semi-automatic can making equipment

The semi-automatic tank welder produced by our company is suitable for welding various materials, such as iron sheet, chrome plated plate, galvanized sheet, stainless steel and so on. Our rolling machine design three processes to complete the rolling machine, so that when the hardness and thickness of the material is different, it avoids the phenomenon of different sizes of the rolling machine.

-

Automatic double circular knife cutting machine

Double circular knife cutting machine, automatic double circular knife cutting machine is suitable for printing iron can industry.

The equipment adopts the world famous brand Japan Mitsubishi series PLC (programmable logic controller with interface) and Mitsubishi Motion as the main control module, and is equipped with Japan Mitsubishi touch screen. The control system components use Schneider. AirTAC is used for pneumatic components. The round knife is made of “Diamond Brand” premium carbide.