Easy handle Semi-automatic Food Tin Can Making Line 1-5L adjustable sardine can making machine

Easy handle Semi-automatic Food Tin Can Making Line 1-5L adjustable sardine can making machine

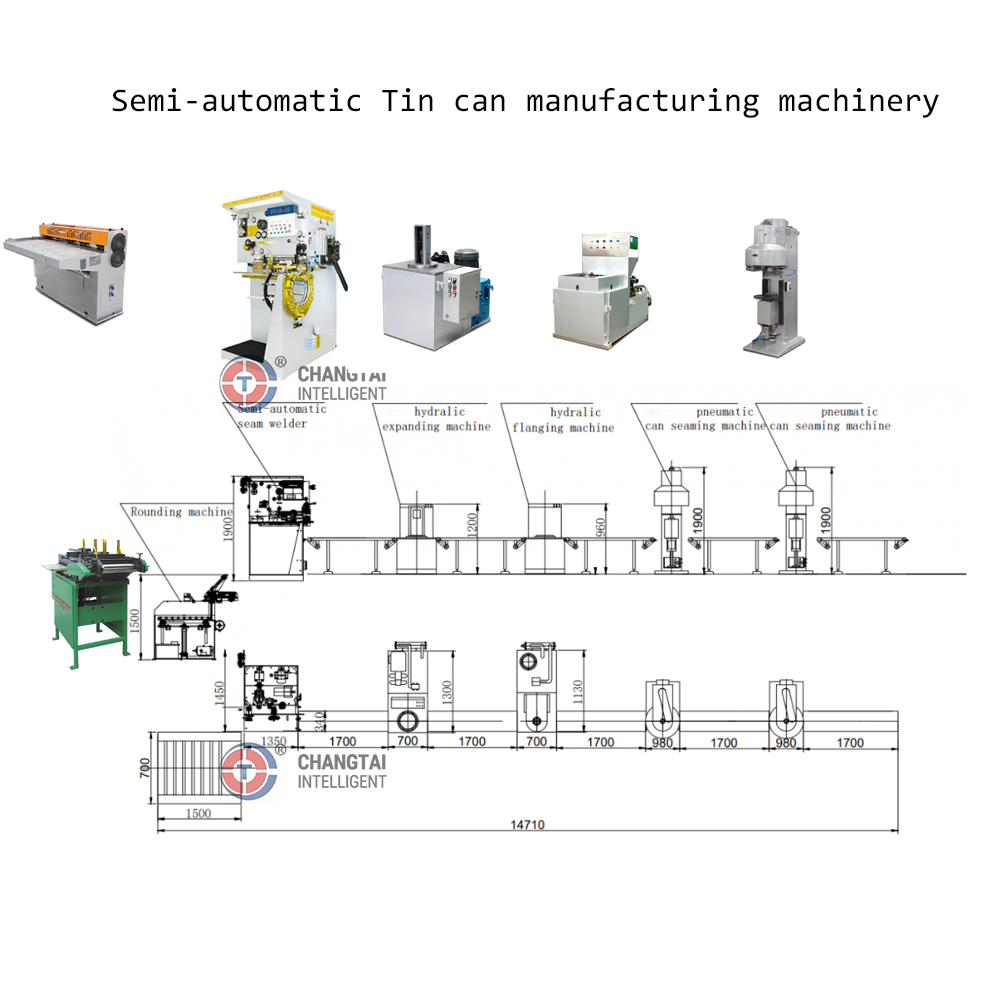

At Changtai's headquarters in Chengdu we develop and build most machines of a can manufacturing system. Our production and assembly plant specializes in manufacturing canbody and drum welders, coating and curing systems, bodyformers and can assembling systems, three-piece canbody making systems. Chengdu is also the home of our R&D center, where new technologies and systems are developed, and existing ones refined.

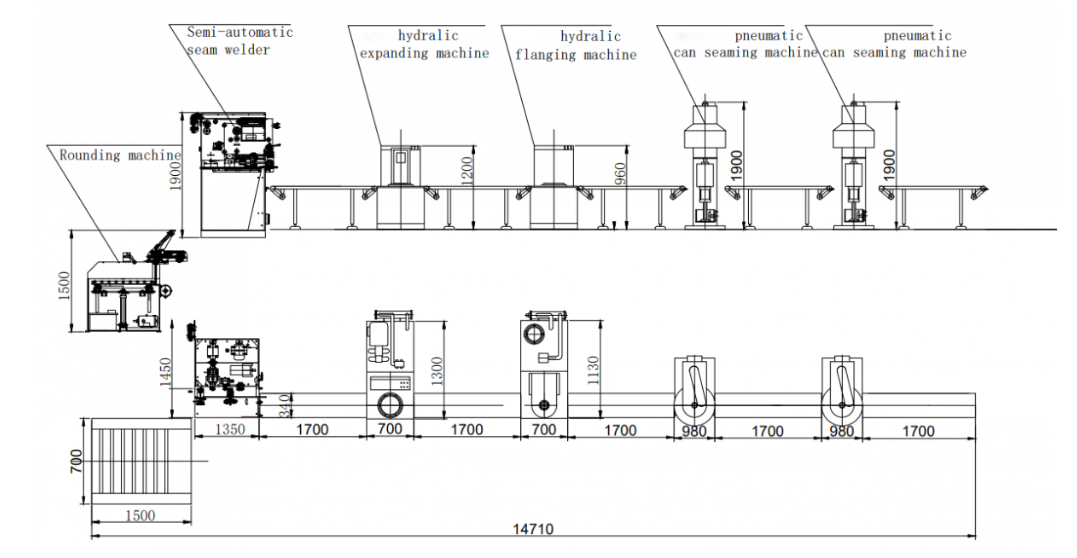

Semi-automatic round can production line

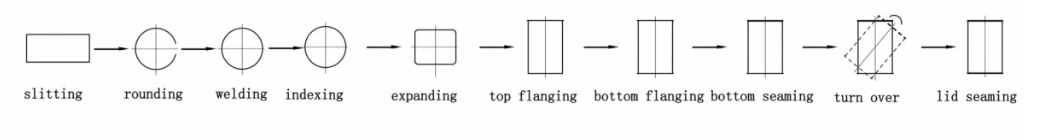

Semi-automatic food can making machineries can be customized and choosable, according to your plant project, for food tin can making,any size, any diameter, any suitable height... The can making production line is suitable for the semi-automatic production of 1-5L tin can, round,square and rectangular food can making. which is composed of three metal plates: can body, can cover and can bottom. The can body is square shaped.Technical flow:cutting the tin sheet to blank-rounding-manual coating-rectangle expanding-upper flanging-lower flanging-bottom seaming-top seaming-packaging

Advantages

♦ MITSUBISHI or PANASONIC PLC and variable-frequency speed governor from Japan.

♦ OMRON Sensor and photoelectric switch form Japan.

♦ SMC Waterway detected flow switch from Japan.

♦ SKF & NSK bearings from Sweden or Japan.

♦ SCHNEIDER electrical appliance components from France.

♦ LG air switch,contactor and circuit breaker from South Korea.

♦ SEMIKRON & SIEMENS control thyristors from Germany.

3 Piece Metal Packaging Industry

| Suitable | Food Chemical,Latex Paint,Motor Oil,Putty,Vacuum Cleaner,Ventilation Pipe. |

| Material | Tinplate,Galvanized, Stainless Steel,Cold Roller Sheet |

| Type | Round/Square/Conical/rectangle |

| Product | Cans,Pails,Drums or Irregularly Shaped Containers |

| Size | 1~30Liter |

Changtai Intelligent offers a range of semi-automatic can making machinery that can be tailored to suit specific packaging requirements. From can dimensions to labeling options, customization ensures that each product receives packaging that enhances its market appeal.

| Production capability | 30-120Cans/min | Applicable can height | 70-320mm 70-280mm |

| Applicable can diameter | Φ50-Φ180mm | Applicable material | Tinplate,steel-based,Chrome plate |

| Applicable material thickness | 0.15-0.35mm | Compressed air consumption | 600L/min |

| Compressed air pressure | 0.5Mpa-0.7Mpa | Power | 380V 50Hz 1KW |

| Machine dimension | 700*1100*1200mm 650*1100*1200mm | ||

| Welding speed | 6-18m/min | Production capability | 20-80Cans/min |

| Applicable height range | 70-320mm and70-420mm | Applicable can diameter | Φ52-Φ180mm&Φ65-Φ290mm |

| Applicable of the material thickness | 0.18~0.42mm | Material | Tinplate,steel-based |

| Point distance | 0.5-0.8mm | Copper wire diameter | Φ1.38mm ,Φ1.5mm |

| The Cooling water |

Temperature:12-18℃ Pressure:0.4-0.5Mpa Discharge:7L/min |

||

| Total power | 18KVA | Machine Dimension | 1200*1100*1800mm |

| Net Weight | 1210Kg | Machine Powder | 380V±5% 50Hz |