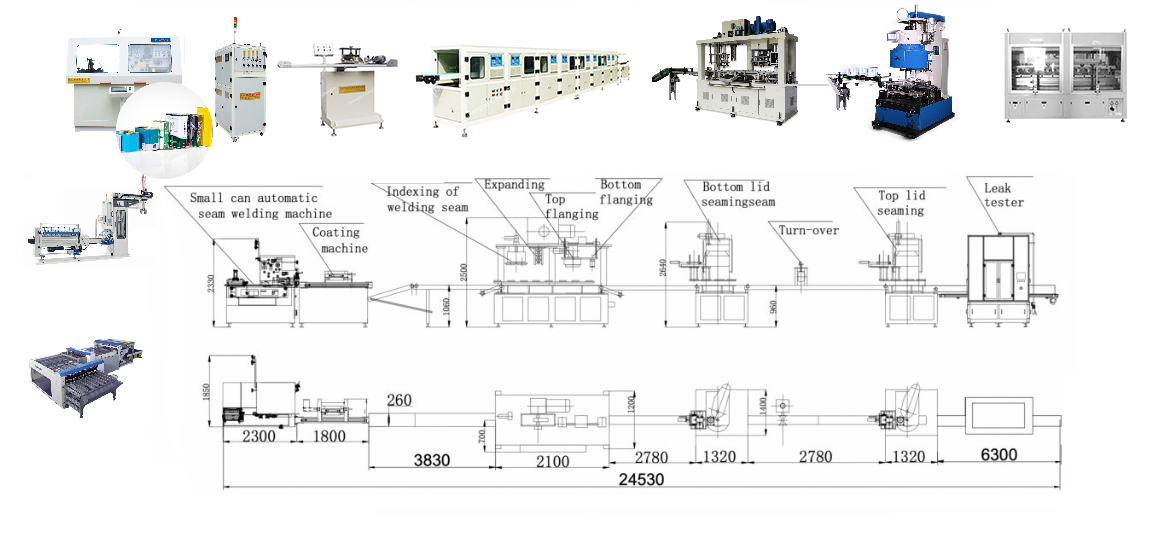

Automatic1-5L rectangular can production line

Automatic1-5L rectangular can production line

Production Video

The automatic 1-5L rectangular can production line is suitable for the automatic production of 1-5L rectangular can.

The machines are customizable according to your cans size and tech-requirements, such as the transfer system, conveyor and palletizing system can be canceled.

Easy operating process

1. Place the cut can body materials into the automatic resistance welding machine's feeding table,Suck by the vacuum suckers,send the tin blanks to the feeding roller one by one.through the feeding roller,the single tin blank is fed to the rounding roller to conduct rounding process,then it will be fed to the rounding forming mechanism to make rounding.

2. The body is fed into the resistance welding machine and make welding after the accurate positioning.

3. After welding,the can body is automatically fed into the rotary magnetic conveyor of the coating machine for outer coating,inner coating or inner powder coating,Which depends on customer's various need.It is mainly used to prevent the side welding seam line from being exposed in air and rusting.

4. The can body is then fed to the small rectangular can combination machine,and the can body is in an upright state going through the uprighting conveyor.It is fed to the first automatic side welding seam indexing station by the clamps.

5. The second station is square expanding.When the can body is in position,on the can body lifting tray which is controlled by a servo motor,and the can body is sent by this lifting tray to the square expanding mold to make square expanding.

6. The third station is to make can body lower flanging.The bottom flanging:the can will be sent to the lower flanging mold lying on the upper part of the machine by lifting tray to make it.

7. The fourth station is to make can body upper flanging.The upper flanging:the upper cylinder will press the can body to the position of top flanging mold to make it.Both the upper and lower can body flanging is each driven by four cylinders.

8. The fifth station is automatic bottom seaming.After the above five steps,the can body will be reversed up and down by a body turner then make top seaming,this process is the same as the bottom seaming process.

Lastly,the finished can is fed by conveyor to automatic leak tester station.After accurate air source inspection,unqualified products are detected and pushed to a fixed area,and qualified products will come to the packaging workbench for the final packaging.

Composition and Tech-Parameter

The duplex metal slitter machine or tinplate sheet slitter machine is one of the most important pieces of equipment in a 3-piece can production line.it is the first station of the can making line. It is used to cut the tinplate sheet or stainless steel sheet as can body blanks of required size or strips for can ends. High quality duplex slitter is the fisrt progress in an optimal solution for metal packaging factory.Versatile, Precise and Robust are the basic requirements for a duplex slitter.

The slitter consists of feeder, shear, electrical control box, vacuum pump, loader and sharpener. The multifunctional slitter is versatility which it can feed automatically, vertical, horizontal cutting automatically, duplex detection and electromagnetism counting.

In short,an automatic duplex slitter works in the procee as follows:

1. Automatic Sheet Feed-in

2. Vertical Slitting,Conveving and positioning, Horizontal slitting

3. Collecting and stacking

| Frequency range | 120-320HZ | Welding speed | 6-36m/min |

| Production capability | 30-200Cans/min | Range of can diameter | Φ52-Φ99mm&Φ65-Φ180mm |

| Range of can height | 55-320mm | Applicable materials | Tinplate,steel-based,Chrome plate |

| Material thickness | 0.16~0.35mm | Applicable copper wire diameter | Φ1.38mm ,Φ1.5mm |

| Cooling water | Temperature: ≤20℃ Pressure:0.4-0.5Mpa Flow:10L/min | ||

| Power | 40KVA | Dimension(L*W*H) | 1750*1500*1800mm |

| Net weight | 1800Kg | Powder | 380V±5% 50Hz |

The automatic can body welding machine is at the heart of any three-piece can production line. It forms the body blanks into their basic shape and welds the seam overlap. Our Superwima welding principle requires only a minimal overlap of a few tenths of a millimeter. Optimum control of the welding current combined with precision-matched pressure on the overlap. Since the launch of the new generation of welders, customers all over the world have confirmed today their considerable satisfaction on an outstanding and a high machine reliability combined with an economical and an efficient production. New industrial standards have been set in the manufacture of canbodies worldwide.

Coating system

Powder coating system is one of the powder coating products launched by Changtai Company. This machine is dedicated to the spray coating technology of tank welds of can manufacturers.

| Model | CTPC-2 | Voltage&Frequency | 380V 3L+1N+PE |

| Production speed | 5-60m/min | Powder consumption | 8-10mm&10-20mm |

| Air consumption | 0.6Mpa | Can body range | D50-200mm D80-400mm |

| Air requirement | 100-200L/min | Power consumption | 2.8KW |

| Machine dimension | 1080*720*1820mm | Gross weight | 300kg |

Powder coating system is one of the powder coating products launched by Changtai Company. This machine is dedicated to the spray coating technology of tank welds of can manufacturers.

| Can height range | 50-600mm | Can diameter range | 52-400mm |

| Roller speed | 5-30m/min | Coating type | Roller coating |

| Lacquer width | 8-15mm 10-20mm | Main supply&Current load | 220V 0.5 KW |

| Air consumption | 0.6Mpa 20L/min | Machine dimension& Net weight | 2100*720*1520MM300kg |

Our company adopts advanced powder coating technology, which makes the machine novel structure, high system reliability, easy operation, wide applicability and high performance-price ratio. And the use of reliable control components, and touch control terminal and other components, making the system more stable and reliable.

The powder coating machine uses static electricity to spray plastic powder on the weld of the tank body, and the solid powder is melted and dried by heating in the oven to form a layer of plastic protective film (polyester or epoxy resin) on the weld. Because the powder can completely and evenly cover the burrs and high and low surfaces on the weld according to the specific shape of the weld by the principle of electrostatic adsorption during spraying, it can well protect the weld from the corrosion of the contents;

At the same time, because the plastic powder has high corrosion resistance to various chemical solvents and sulfur, acid and high protein in food, the powder spraying is suitable for a variety of different contents; And because the excess powder after powder spraying adopts the principle of recycling and reuse, the powder utilization rate is high, and it is the most ideal choice for weld protection at present.

What is seam coating machine and its application?

After welding, the inner and outer seaming should be coated by durable protective layer, then the weld seam will not be rusty. Wet lacquer seam coating machine is random collocation for various requirement, the seam inside can be roller coating or spray coating, the seam outside can be roller coating, spray coating or drop coating. The side seam coating machine is versatile for weld seam of food cans, beverage cans and aerosol cans as well as industrial packaging containers. The can coater is easy to adjust and low consumption of lacquer.

According to the coating solution, the lacquer coating machine is flexible, for the inside coating, We can design it as spray or roller coating, for the outside coating, it can be roller coating or drop coating. The can manufacturer can select the suitable device for free combination.

Application:

Coating machine can be used widely in metal can manufacturing industry, to protect the welded side seam from corrosion and rust.the machine is suitable for :

1. General line can making

2. 3-piece food can making

3. Aerosol can making

4. Conical pail or chemical pail making

5. Necking pail or solvent pail making

6. Paint can making

Conveying spray machines play a significant role in the can manufacturing industry. Through automation integration, multi-functional coating capabilities, energy-efficient design, quality control, and innovative coating technologies, these machines provide efficient, reliable, and competitive production solutions for can manufacturers.

An induction curing system or drying machine for can-body welding is an essential component of the production machine line for food, beverage, and milk powder can manufacturing. It is used to dry the cans after the coating or printing process, ensuring proper curing and adhesion of the applied materials.

The overall productivity and quality of the can production process. in the back of its(curing system) efficient drying capabilities, precise temperature control, compact design, energy efficiency, and safety features.

| Conveyor speed | 5-30m/min | Can diameter range | 52-180mm |

| Conveyor type | Flat chain drive | Cooling diduct. coil | Not require water/air |

| Effictive heating | 800mm*6(30cpm) | Main supply&Current load | 380V+N>10KVA |

| Heating type | Induction | Sensing distance | 5-20MM |

| Higher Heating | 1KW*6(temperature set) | Induction point | 40MM |

| Frequency setting | 80KHz+-10 KHz | Induction time | 25Sec(410mmH,40CPM) |

| Electro.Radiation protective | Covered with safety guards | Rise time(MAX) | Distance 5mm 6sec&280℃ |

| Dimension(L*W*H) | 6300*700*1420mm | Net Weight | 850KG |

Changtai has a modular range of curing systems designed to harden the seam protection layer effectively. Immediately after the application of the lacquer or powder seam protection layer, the canbody goes heat treatment. We have developed advanced gas or induction-operated modular heating systems with automatic temperature regulation and speed-adjustable conveyor belts. Both heating systems are available in linear or U-shape layout.

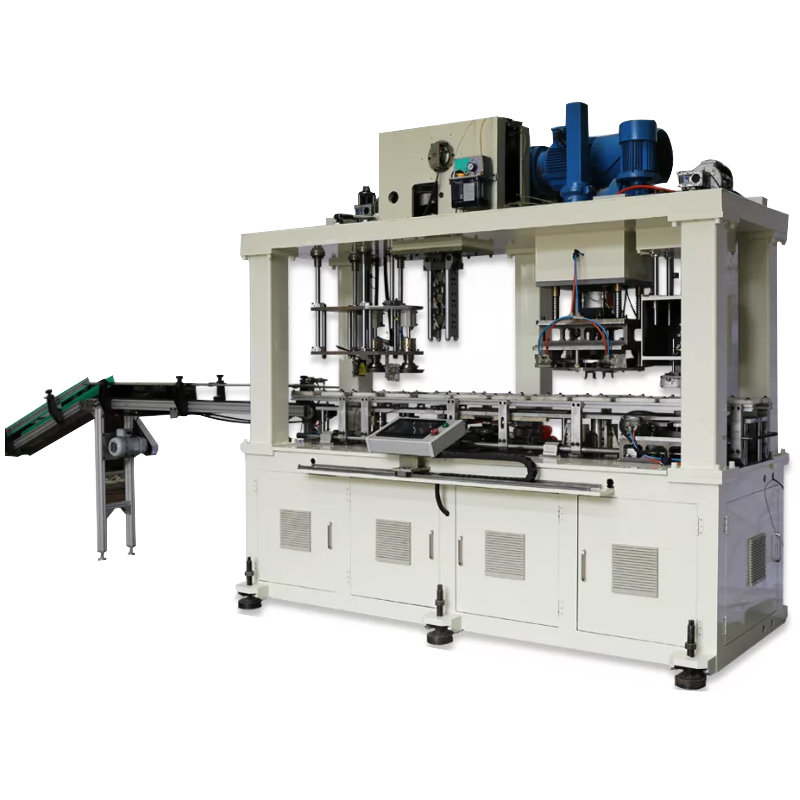

Canbody forming and assembling

Canbody Combination Machine

| Production capacity | 30-35cpm | Can Dia. range | 110-190mm |

| Can height range | 110-350mm | thickness | ≤0.4 |

| Power | 26.14kw | Pneumatic system pressure: | 0.3-0.5Mpa |

| Body uprighting conveyor size | 2250*230*920mm | Infeed conveyor size | 1580*260*920mm |

| Combination machine size | 2100*1500*2340mm | Net Weight | 4T |

| Electric carbinet Dimension | 700*450*1700mm | ||

Automatic can seaming machine

| production capacity | 35cpm |

| diagonal range | 50-190m |

| can height range | 80-350mm |

| thickness | ≤0.35mm |

| total power | 5.13KW*2 |

| pneumatic system pressure: | 0.5Mpa |

| the front section conveyor’s size | (2740*260*880mm)*2 |

| seaming machine size | (1100*310*950mm)*2 |

| seaming machine weight | 2.5T*2 |

Our Can reformer machine and can body shape forming machine are suitable for a wide range of applications, including parting, shaping, necking, flanging, beading and seaming. With fast, simple retooling, they combine extremely high productivity with top product quality, while offering high safety levels and effective protection for operators.

In Tin Can Making, the Combination Machine,

combines the Flanging, Beading And Seaming functions in one process.

The flanging, beading, and seaming combination machine provides a multi-functional integrated operation for tin can manufacturing. It can perform the processes of flanging, beading, and seaming, combining multiple steps into a single machine, greatly enhancing production efficiency and effectiveness.

Leak tester

| Detected product volume range | 1-5L |

| Equipment air pressure | 4-6Bar |

| Check pressure | 10-15Kpa |

| Detection accuracy | 0.17mm |

| Detection speed | 30PCS/mins |

| Device Weight | 1500KG |

| Dimensions(L*W*H) | 3200mm*950mm*2200mm |

| Input power | 380v/50HZ |

We provide leak testers for all sizes and shapes of cans and for pails and drums of all sizes.

When the metal containers or plastic containers are completed by the can making line, the containers are come into leak inspecting machine, that is commonly named as can tester, pail tester or drum tester depending to the detected object. The leakage tester inspects and detects the containers by air, the containers can be fed as linear or rotary. For the general line cans or pails, the speed of can production line is not so high, it is better to use the in-line leak tester layout as linear, and for the aerosol cans or small space room, it is better to use the rotative can testing machine.

Palletizing system

| Work height suitable pallet size | 2400mm |

| suitable pallet size | 1100mm×1400mm;1000mm x 1200mm |

| Production capability | 300~1500 cans/min |

| Applicable can size | Diameter 50mm~153mm, height: 50mm~270mm |

| Applicable product | All kinds of tinplate can, glass bottle and plastic bottle |

| Dimension | Length 15000mm (without film wrapper)×width 3000mm×height 3900mm |

| Power supply | 3×380V 7KW |

A can production line usually ends with a palletizer. The pail assembly line can be customized, which will ensure stacks that can be palletized in a next steps. Some customers get workers to do this job.

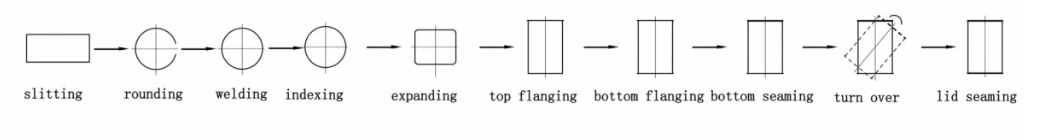

Tin can making artcraft

1-5L rectangular can flowing chart

Company Profile

Started in 2007, Chengdu Changtai has been devoting in can makingmachine for 20 years, has presently become a national advanced technol-ogy enterprise possessing more than ten invention patents.We have a first-rate team of talented engineers and technicianswith extensive experience in three-piece can making and as well as in researching and applying optical, digital, electrical in canning machinery. Via ISO9001,SGS and BV certified, make it be the well-known can making machinery brand in China.