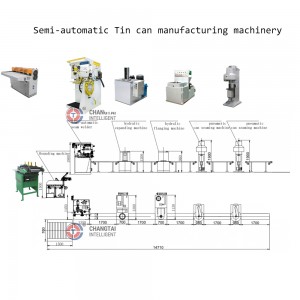

0.1-5L semi-automatic round can production line

0.1-5L semi-automatic round can production line

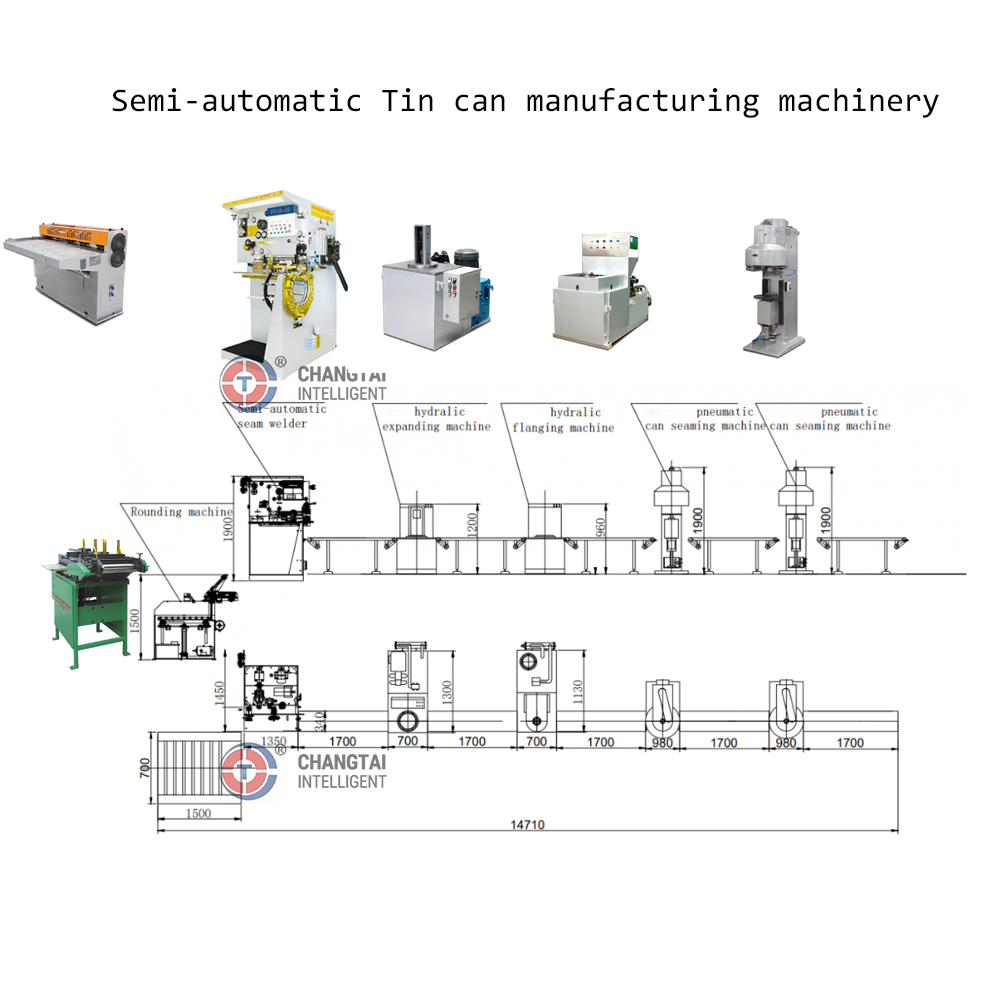

Semi Automatic Can making solution for food cans

Changtai Intelligent supplies the 3-pc can making machinery. All the parts are well processed and with high precision. Before delivering, the machine will be tested to assure the performance. Service on Installation, Commissioning, Skill training, Machine repaire and overhauls, Trouble shooting, Technology upgrades or kits conversion,Field Service will be provided kindly.

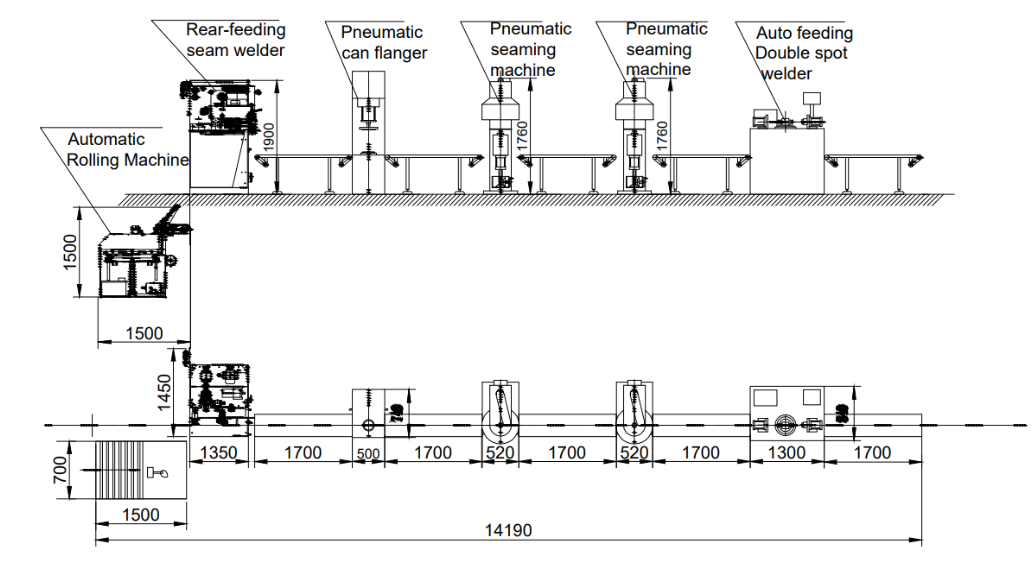

Semi-automatic round can production line

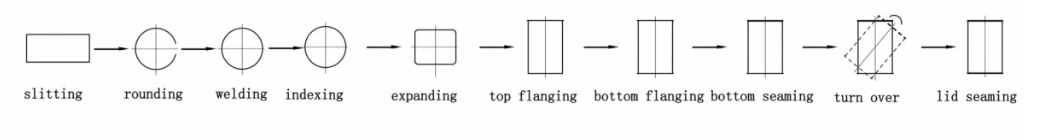

The can making production line is suitable for the semi-automatic production of 0.1-5L round can, which is composed of three metal plates: can body, can cover and can bottom. The can body is round.Technical flow:cutting the tin sheet to blank-rounding-welding-manual coating-flanging-bottom seaming-top seaming-ear lug welding-packaging

Features

1.Panasonic PLC and Mitsubishi frequency conversion speed governor control system,

2.Welding frequency is adjustable with constant current and attenuation function at front & back end

3.Sensor can precise control the welding current location at front & back end,change copper wire speed.

4.Change the gauge tooling can welding different size of cans.

5.Comprehensive monitoring the equipment running,with failure self-detected alarms and provide solution system.

6.Apply to the welding of various flashlight,small aerosal cans.

7.Can body internal and external pre-painting machine and can body drier are optional to be added in production line.

8.According to customer’s demands to accelerate speed.

| Production capability | 30-120Cans/min | Applicable can height | 70-320mm 70-280mm |

| Applicable can diameter | Φ50-Φ180mm | Applicable material | Tinplate,steel-based,Chrome plate |

| Applicable material thickness | 0.15-0.35mm | Compressed air consumption | 600L/min |

| Compressed air pressure | 0.5Mpa-0.7Mpa | Power | 380V 50Hz 1KW |

| Machine dimension | 700*1100*1200mm 650*1100*1200mm | ||

| Welding speed | 6-18m/min | Production capability | 20-80Cans/min |

| Applicable can height | 70-320mm&70-420mm | Applicable can diameter | Φ52-Φ180mm&Φ65-Φ290mm |

| Applicable material thickness | 0.18~0.42mm | Applicable material | Tinplate,steel-based |

| Semi point distance | 0.5-0.8mm | Applicable copper wire diameter |

Φ1.38mm ,Φ1.5mm |

| Cooling water |

Temperature:12-18℃ Pressure:0.4-0.5Mpa Discharge:7L/min |

||

| Total power | 18KVA | Dimension |

1200*1100*1800mm |

| Weight | 1200Kg | Powder | 380V±5% 50Hz |