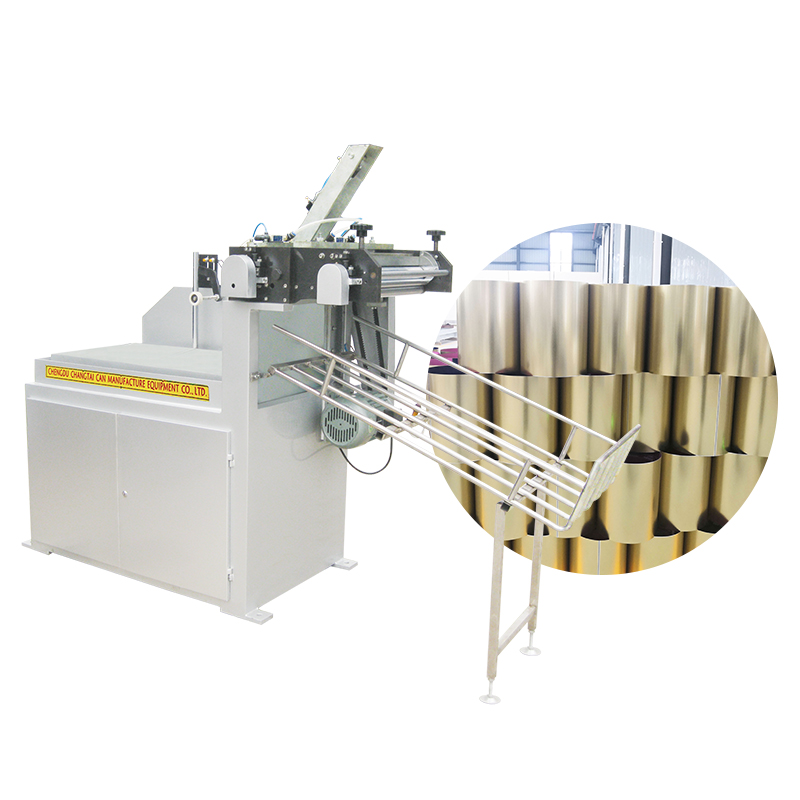

1L-25L Square Cans Oil Cans Round Cans Food Cans Automatic Round-Forming Machine

1L-25L Square Cans Oil Cans Round Cans Food Cans Automatic Round-Forming Machine

Technical Parameters

| Model | ZDJY120-320 | ZDJY120-280 |

| Production Capacity | 30-120cans/min | |

| Can Diametre Range | 50-180mm | |

| Can Height Range | 70-320mm | 70-280mm |

| Material | Tinplate/steel-based/chrome plate | |

| Tinplate Thickness Range | 0.15-0.35mm | |

| Compressed air consumption | 600L/min | |

| Pressure of Compressed air | 0.5Mpa-0.7Mpa | |

| Power Supply | 380V±5% 50Hz 1Kw | |

| Machine Measurements | 700*1100*1200mm | 650*1100*1200mm |