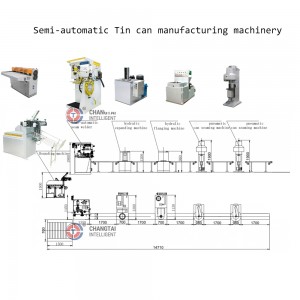

10-20L semi-automatic square can production line

10-20L semi-automatic square can production line

Designed for easy handling and quick to learn for the canmakers, the parameters of this can production line as below:

Features

| PLC | Panasonic in Japan |

| Frequency Converter | Mitsubishi in Japan |

| Photoelectric Switch | Panasonic in Japan |

| Rotary Encoder | OMRON in Japan |

| Water Detection Switch | SMC in Japan |

| Low-voltage Electrical Appliances | Schneider in France |

| Welding Wheel Material | Beryllium Copper |

| Z-bar Materia | Carbide |

Changtai Intelligent continually pushes the boundaries of innovation, incorporating advanced technologies to enhance machine functionality and performance. From automated quality control systems to real-time monitoring capabilities, these innovations empower food producers to stay ahead in a rapidly evolving market.

Semi-automatic round can production line

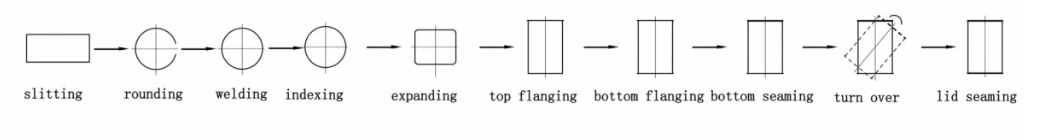

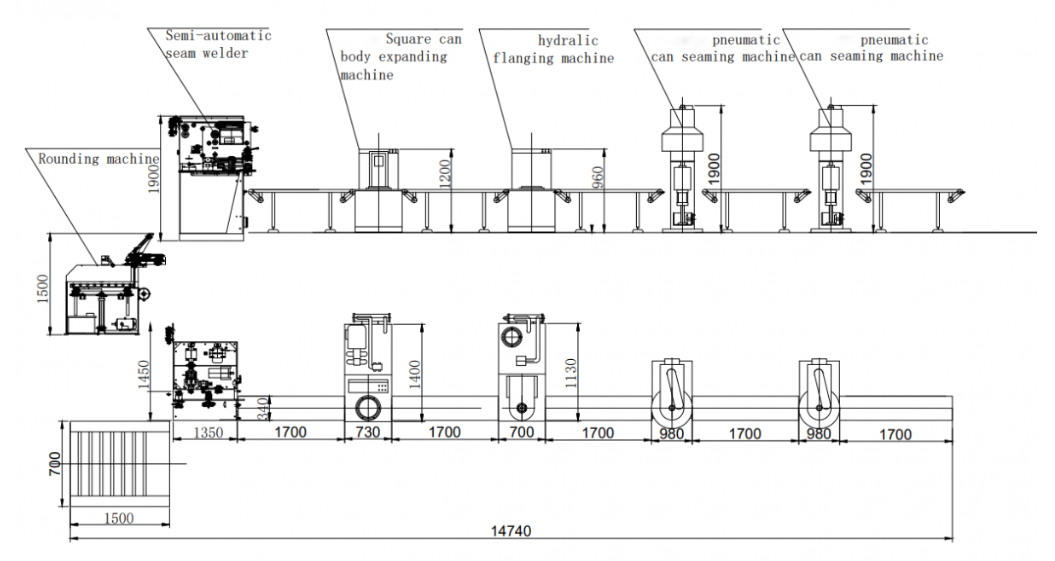

The can making production line is suitable for the semi-automatic production of 10-20L square can, which is composed of three metal plates: can body, can cover and can bottom. The can body is square shaped.Technical flow:cutting the tin sheet to blank-rounding-welding-manual coating-square expanding&panel and corner embossing-upper flanging-lower flanging-bottom seaming-top seaming-packaging

| Production capability | 10-80Cans/min 5-45Cans/min | Applicable can height | 70-330mm 100-450mm |

| Applicable can diameter | Φ70-Φ180mmΦ99-Φ300mm | Applicable material | Tinplate,steel-based,Chrome plate |

| Applicable material thickness | 0.15-0.42mm | Compressed air consumption | 200L/min |

| Compressed air pressure | 0.5Mpa-0.7Mpa | Power | 380V 50Hz 2.2KW |

| Machine dimension | 2100*720*1520mm | ||

| Welding speed | 6-18m/min | Production capability | 20-80Cans/min |

| Applicable can height | 70-320mm&70-420mm | Applicable can diameter | Φ52-Φ180mm&Φ65-Φ290mm |

| Applicable material thickness | 0.18~0.42mm | Applicable material | Tinplate,steel-based |

| Semi point distance | 0.5-0.8mm | Applicable copper wire diameter |

Φ1.38mm ,Φ1.5mm |

| Cooling water |

Temperature:12-18℃ Pressure:0.4-0.5Mpa Discharge:7L/min |

||

| Total power | 18KVA | Dimension |

1200*1100*1800mm |

| Weight | 1200Kg | Powder | 380V±5% 50Hz |