ABOUT COMPANY

Changtai

Intelligent Equipment

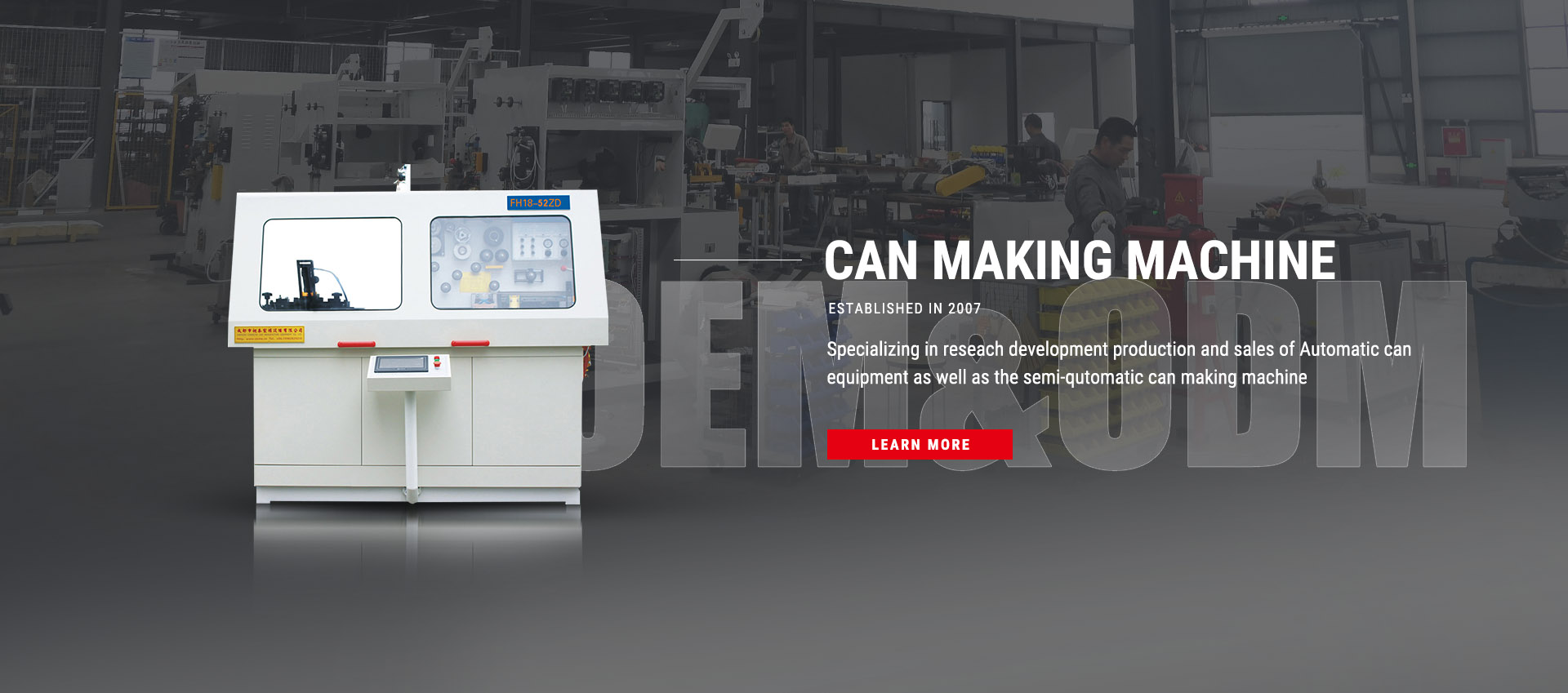

Chengdu Changtai Intelligent Equipment Co., Ltd. a professional Manufacturer and Supplier of Can Making Machinery, established in 2007. Our automatic can-making equipments are widely used in the production of can packaging for industries such as paint, chemical, oil, food and so forth.

Changtai Intelligent supplies the 3 PIECE Can Making Machinery. All the parts are well processed and with high precision. Before delivering, the machine will be tested to assure the performance. Service on Installation, Commissioning, Skill training, Machine repaire and overhauls, Trouble shooting, Technology upgrades or kits conversion,Field Service will be provided kindly.

LEARN MORE

-

Professional Team

Professional technical team, R&D team, production and after-sales team can achieve full tracking service, one-to-one service, and provide suitable solutions for you.

LEARN MORE -

Independent R&D

The company has a professional R&D team, all of whom have more than 20 years of experience in the canning machinery industry, and have obtained a number of practical patent certificates

LEARN MORE -

ODM&OEM

The unique production needs and design of can making machinery and equipment can be perfectly solved by our design and development team.

LEARN MORE -

Quality Assurance

Our mechanical accessories and parts are all well-known brands at home and abroad, and each equipment has a 1-year warranty period to eliminate your worries.

LEARN MORE -

Factory Supply

With a factory production base covering an area of more than 8,000 square meters, advanced processing and production equipment, multiple production lines can be supplied at the same time.

LEARN MORE -

Perfect after-sale

We have an efficient after-sales team to provide you with 24-hour service one-on-one and a dedicated technical after-sales team to directly connect with your engineers and communicate effectively.

LEARN MORE

Our food can production line is widely used, not only can produce canned food, pet food and other tin can packaging, but also can produce beverage, milk powder and other tin can packaging. Adapt to various diameters and heights of food cans, beverage cans, milk powder cans, our can production line can easily complete. As a food can, metal cans have many advantages. Not only can they ensure the freshness of food, but their packaging has the highest recycling rate of all food packaging, which can not only be processed and reused, but also save a lot of energy and landfill space.

Chemical metal packaging is widely used in various forms, so the production line design of our metal cans (such as: paint cans, oil cans, ink cans, glue cans) is more flexible, and can fully meet the special requirements of paints, coatings and adhesives. Although the shape and speed of metal containers are variable, our can production line can fully meet various requirements of round cans, rectangular cans and square cans, such as: 1-5L paint can production line, 1-6L rectangular can production line, 18L square can production line tank manufacturing lines, etc.

When metal cans are used to produce aerosol cans, pressure and air tightness are the primary considerations. Our aerosol can production line is equipped with gas inspection machines and water inspection machines for customers to choose on demand for accurate detection of aerosol cans leakage, improving production quality and ensuring safety. At the same time, the aerosol can production line is equipped with an external coating machine that can automatically spray glue to ensure the sealing of the welding seam. After the repair coating is completed, a high-frequency electromagnetic dryer that can adjust the power and does not require cold water to complete the drying of the welding seam. The production line is scientifically designed to ensure the air tightness of the aerosol can.

We specialize in the research and development of large barrel production line, the volume of the barrel can be 50L, such as: 50L oil barrel, beer barrel, chemical raw material barrel, etc. Our Automatic can Body Welding Machine can accept ultra-thick plate welding, welding speed is fast; The operation is simple. The whole production process requires less labor, full automation production degree is high. And in the same can body material, the welding speed and yield, faster than all other manufacturer of welding machine, and the highest yield (including weld quality, appearance, roundness, indentation, chafed, etc), after they use for a long time, in the process of machine maintenance rate is the lowest, in the process of manufacturing the same number of products, spare parts cost is lowest. Our welding machine does not have much requirements on the shape of the can, and it can be applied to a wide range of materials, such as tin plate, iron base plate, chrome plate, galvanized plate and so on.

-

Chinese New Year Holiday Notice & New Year Greetings (2026)

Dear Valued Customers, Partners, and Friends: As the warm winds of spring herald the arrival of a new year, we are pleased to announce the upcoming celebration of the Chinese New Year (Lunar New Year) 2026, the Year of the Horse. On behalf of the entire team at Chengdu C...

-

Beyond Speed: Analyzing How CE-Certified Automatic Can Body Welding Machines Are Redefining Packaging Line Efficiency

In an era where manufacturing efficiency is increasingly measured by more than just output speed, the metal packaging industry faces a new set of imperatives: precision, reliability, and seamless system integration. The traditional focus on high-throughput machinery is giving way to a more holist...

-

The “Invisible Guardian” Against Can Rust

Weld Powder Coating Machine: The "Invisible Guardian" Against Can Rust The CTPC series weld powder coating machine is an electrostatic coating equipment launched by Chengdu Changtai Intelligent Equipment Co., Ltd., suitable for the ...