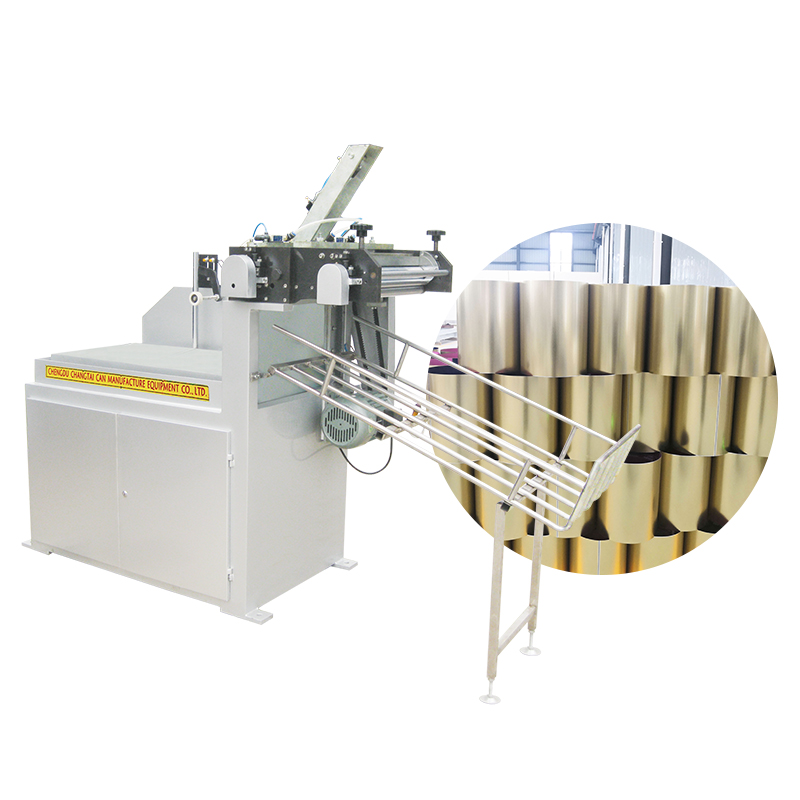

Station combination machine (Flanging/Beading/Seaming)

Station combination machine (Flanging/Beading/Seaming)

Technical Parameters

|

Fuction |

Flanging.Beading.Double Seaming(Roll) |

|

Madel type |

6-6-6H/8-8-8H |

|

Range of can Dia |

52-99mm

|

|

Range of can height |

50-160mm(beading:50-124mm) |

|

Capacity per min.(MAX) |

300cpm/400cpm |

Introduction

The Station Combination Machine is an advanced piece of equipment used in the can manufacturing industry. It combines multiple operations into one unit, making it a key player in producing metal cans like those for food, beverages, or aerosols.

Functions and Processes

This machine typically includes stations for:

Flanging: Forming the edge of the can body for later sealing.

Beading: Adding reinforcement to strengthen the can structure.

Seaming: Securely attaching the top and bottom lids to create a sealed can.

Advantages

The machine offers several benefits:

Efficiency: Integrates processes, reducing the need for separate machines and speeding up production.

Space Saving: Takes up less floor space compared to individual machines, ideal for compact factories.

Cost-Effectiveness: Lowers equipment and maintenance costs, potentially reducing labor needs.

Versatility: Can handle various can sizes and types, offering flexibility in production.

Quality: Ensures consistent, high-quality cans with strong, leak-proof seals, thanks to precision engineering.

This combination approach seems likely to streamline manufacturing, making it a cost-effective and efficient solution for producers.