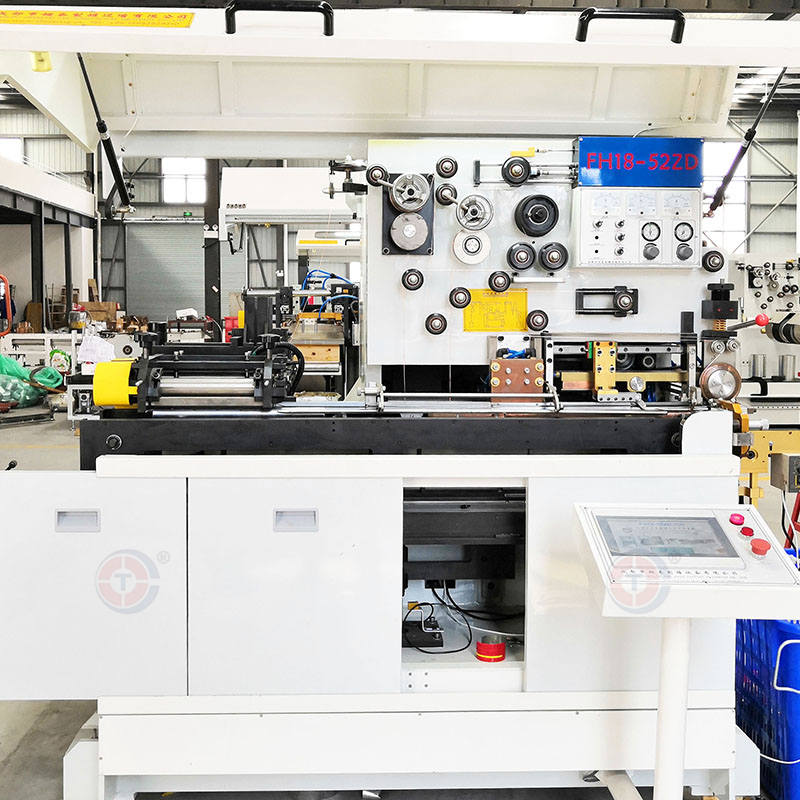

200-401 Tin Can Welding Machine 170ml-2.5L tin can production line

200-401 Tin Can Welding Machine 170ml-2.5L tin can production line

The canbody former: Can welding machine

What is a can welding machine?

Can welding machine, also called as pail welder, can welder or welding bodymaker,The canbody welder is at the heart of any three-piece can production line. As the Canbody welder take resistance welding solution to weld side seam, it is also named as side seam welder or side seam welding machine.

Application

Can welding machine is used to suck and roll the can body blanks, through Z-bar to control the overlap, and weld blanks as can bodies, also named as can welder or welding bodymaker.Because the can body welder employs resistance welding solution to weld side seam, it is also named as side seam welder or side seam welding machine.The canbody welder can connect to the seam coating machine through lower arm, then the cans from canbody welding machine will be conveyed horizontally and smoothly.The metal can welding machine is widely used for various size of metal containers by changing over calibration unit, then the tin can welder is flexible and applied widely.

Short details about this Tin Can Welding Machine

The machine’s copper wire cutting knife is made of alloy material that has a very long service life.

It is simple and clear for the touch screen operation interface.Our machine is equipped with various protection measures. when there is a fault,machines will be automatically showed on the touch screen and prompted to deal with it. Programmable logic controller (PLC) input and output points can be read directly on the touch screen while checking machine movement,.

The stroke of the welder table is 300mm, and the back of the welder is equipped with a table, which can be loaded by a forklift, reducing the time for adding iron. The round cutting adopts the suction type, the cutting size of the iron sheet is low, there is no need to adjust the material frame of the round cutting machine to change the pot type.

The feeding tank is made of stainless steel integrated tank. Quick change of tank type. Each diameter is provided with a corresponding tank delivery channel. You only need to remove two screws, remove the tank slot of the tank delivery station, and then install another tank slot, so that a change of tank type only takes 5 minutes.

LED lights are set on the front of the machine and above the roll to observe the running state of the machine

Technical Parameters

| Model | FH18-52ZD-200 | FH18-52ZD-260 | FH18-52ZD-320 |

| Liner rate of welding | 6-26m/min | 10-26m/min | 10-36m/min |

| Production Capacity | 100-200cans/min | 30-120cans/min | 30-100cans/min |

| Can Diameter Range | 52-99mm | ||

| Can Height Range | 55-200mm | 70-280mm | 70-320mm |

| Material | Tinplate/steel-based/chrome plate | ||

| Tinplate Thickness Range | 0.16-0.3mm | ||

| Applicable material Thickness | 1.38mm 1.5mm | ||

| Cooling Water | Temperature :<=20℃ Pressure:0.4-0.5MpaDischarge:10L/min | ||

| Power Supply | 380V±5% 50Hz | ||

| Total Power | 63KVA | 40KVA | 40KVA |

| Machine Measurements | 1750*1100*1800 | ||

With more than 17 years’ experience on can making technology ,we are able to give customers engineering advises and help customers to find qualified products and good solutions for their projects.

Please contact us for your Automatic Can Making Line Solutions