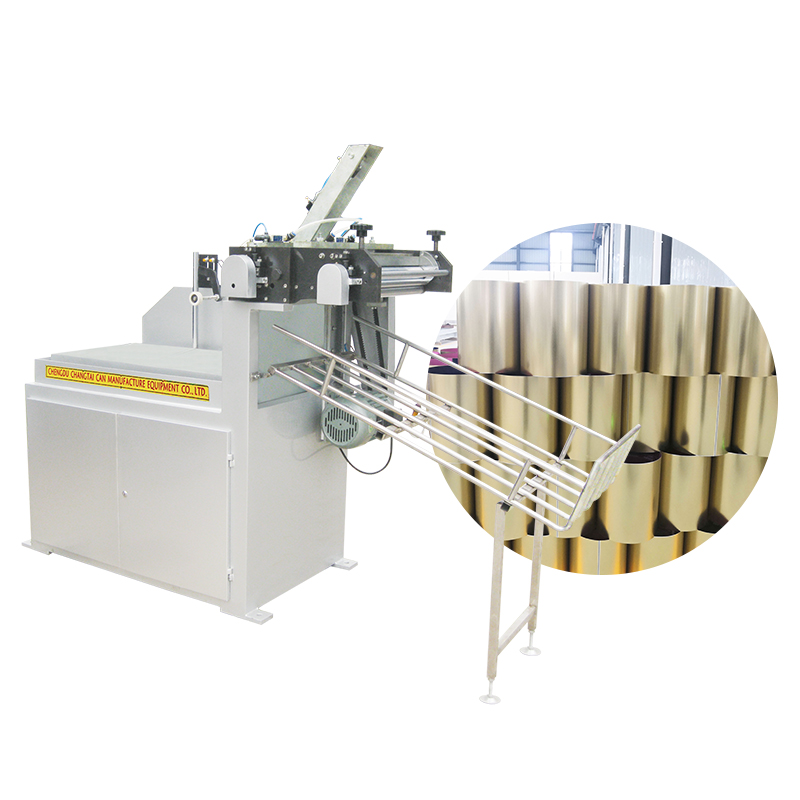

Round cans square cans round-forming machine can making machine

Round cans square cans round-forming machine can making machine

Changtai Can making equipment

Changtai Intelligent supplies the 3-pc can making machinery.

All the parts are well processed and with high precision. Before delivering, the machine will be tested to assure the performance.

Service on Installation, Commissioning, Skill training, Machine repaire and overhauls, Trouble shooting, Technology upgrades or kits conversion,Field Service will be provided kindly.

Technical Parameters

| Model | ZDJY80-330 | ZDJY45-450 |

| Production Capacity | 10-80cans/min | 5-45cans/min |

| Can Diametre Range | 70-180mm | 90-300mm |

| Can Height Range | 70-330mm | 100-450mm |

| Material | Tinplate/steel-based/chrome plate | |

| Tinplate Thickness Range | 0.15-0.42mm | |

| Compressed air consumption | 200L/min | |

| Pressure of Compressed air | 0.5Mpa-0.7Mpa | |

| Power Supply | 380V±5% 50Hz 2.2Kw | |

| Machine Measurements | 2100*720*1520mm | |

Details

The rounding machine consists of 12 shafts (end bearings are evenly installed at both ends of each power shaft), and three knives to form a rounding channel.

When each can is rolled, it is pre-rolled by three shafts, six shafts, three knives, kneading iron, and three knives.

It is completed after the shaft is rolled into a circle. It overcomes the problem of different sizes of rolled cans due to different materials; after this treatment, the rolled cans have no obvious edges, corners and scratches (coated iron is the easiest to see).

Each axis of the rolling machine adopts centralized oiling method, which is convenient and saves maintenance time.

In order to prevent the scratching of the can body during the high-speed delivery, multiple pieces of reinforced glass are used as the tank support plate under the roll circle of the can delivery channel, and imported PVC nylon bearings are used for the tank protection track.

In order to ensure that the rounded can body is accurately fed into the protective cage, an air cylinder presses the tank guard plate to push it forward when sending the can.