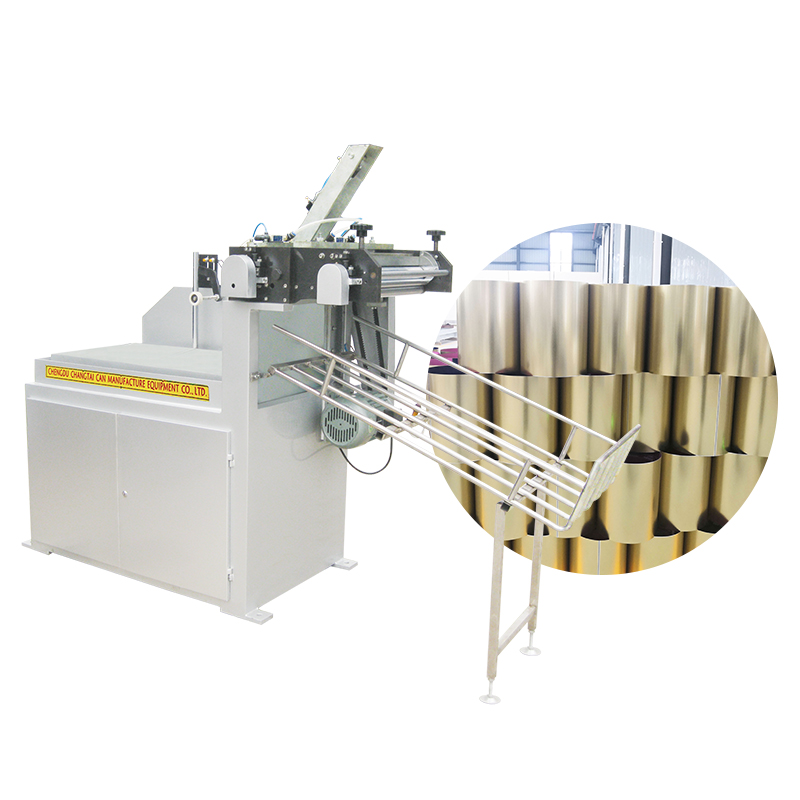

10L-25L tin can making machine metal food cans semi-automatic can welding machine

10L-25L tin can making machine metal food cans semi-automatic can welding machine

Semi-automatic canbody welding machines offer a balance between manual control and automation in the canmaking process, providing flexibility and efficiency in forming can bodies. These machines automate the welding of metal sheets (typically tinplate) to create the cylindrical can shape, with operators having the ability to adjust parameters during the process. They are particularly useful for smaller production runs, custom can sizes, or when specialized materials require close supervision

Advantages:

One of the key advantages of a semi-automatic can welding machine is its ability to increase production efficiency while maintaining high-quality welds. Operators can quickly set up the machine for different can sizes, which reduces downtime during production changes. The semi-automatic nature allows for human oversight, ensuring that quality control is upheld without the need for fully manual operation. Additionally, these machines are typically more cost-effective than fully automatic models, making them accessible for small to medium-sized manufacturers. They also offer greater adaptability to various welding techniques, such as spot welding and seam welding, catering to diverse production needs.

Application Industries:

Semi-automatic can welding machines find application across various industries. The most prominent is the food and beverage industry, where they are used to manufacture aluminum and tin cans for products like soda, beer, and canned goods. Other applications include the cosmetics and personal care industries, where metal packaging is crucial for product preservation and aesthetics. Overall, the versatility of semi-automatic can welding machines makes them essential in any industry that requires reliable and efficient can production.

Technical Parameters

| Model | FH18-65 |

| Welding Speed | 6-18m/min |

| Production Capacity | 20-80cans/min |

| Can diameter Range | 65-286mm |

| Can Height Range | 70-420mm |

| Material | Tinplate/steel-based/chrome plate |

| Tinplate Thickness Range | 0.18-0.42mm |

| Z-bar Oerlap Range | 0.6mm 0.8mm 1.2mm |

| Nugget Distance | 0.5-0.8mm |

| Seam Point Distance | 1.38mm 1.5mm |

| Cooling Water | Temperature 12-18℃ Pressure:0.4-0.5MpaDischarge:7L/min |

| Power Supply | 380V±5% 50Hz |

| Total Power | 18KVA |

| Machine Measurements | 1200*1100*1800 |

| Weight | 1200kg |

What is Canbody making machine?

Can welding machine-CMM (Canbody making machine), also called as pail welder, can welder or welding bodymaker,The canbody welder is at the heart of any three-piece can production line. As the Canbody welder take resistance welding solution to weld side seam, it is also named as side seam welder or side seam welding machine.

Canbody welder is used to suck and roll the can body blanks, through Z-bar to control the overlap, and weld blanks as can bodies.

Why choose Changtai for your canbody making machine supplier?

Chengdu Changtai Intelligent Equipment Co., Ltd.(Chengdu Changtai Can Manufacture Equipment Co,.Ltd) is located in the Chengdu city,beautiful and rich in natural resources.The company was founded in 2007,is a science and technology private enterprise, having advanced foreign technology and high quality equipment.We combined the domestic industrial demand character, specializing in research, development, production and sales of automatic can equipment, as well as the semi-automatic can making equipment, etc.

Why choose Changtai for your canbody making machine supplier?

Chengdu Changtai Intelligent Equipment Co., Ltd.(Chengdu Changtai Can Manufacture Equipment Co,.Ltd) is located in the Chengdu city,beautiful and rich in natural resources.The company was founded in 2007,is a science and technology private enterprise, having advanced foreign technology and high quality equipment.We combined the domestic industrial demand character, specializing in research, development, production and sales of automatic can equipment, as well as the semi-automatic can making equipment, etc.

Our company covers an area of 5000 square meters, own the advanced processing and production equipment, there are professional research and development personnel 10 people, production and after-sales service more than 50 people, furthermore, the R&D manufacturing department provides a powerful guarantee for the advanced research.production and well after-sales service.

Changtai Intelligent supplies the 3-pc can making machinery. All the parts are well processed and with high precision. Before delivering, the machine will be tested to assure the performance. Service on Installation, Commissioning, Skill training, Machine repaire and overhauls, Trouble shooting, Technology upgrades or kits conversion,Field Service will be provided kindly.

Our Can reformer machine and can body shape forming machine are suitable for a wide range of applications, including parting, shaping, necking, flanging, beading and seaming. With fast, simple retooling, they combine extremely high productivity with top product quality, while offering high safety levels and effective protection for operators.