The Three-Piece Can Industry and Intelligent Automation

The three-piece can manufacturing industry, which produces cylindrical can bodies, lids, and bottoms primarily from tinplate or chrome-plated steel, has seen significant advancements through intelligent automation. This sector is vital for packaging in diverse industries, including food, beverages, chemicals, and medical products, where durability and safety are paramount. Intelligent automation, integrating technologies like artificial intelligence (AI), machine learning, and robotics, has transformed production by enhancing efficiency, reducing costs, and improving product quality. For instance, AI-powered systems enable real-time monitoring and optimization, such as predictive maintenance to prevent machine breakdowns and machine vision for quality control, ensuring uniformity across batches.

Introduction to Three-Piece Can Manufacturing

Three-piece can manufacturing involves creating cylindrical can bodies, lids, and bottoms, primarily using tinplate or chrome-plated steel. This industry serves packaging needs in food, beverages, chemicals, and medical products, requiring high precision and durability. Automation plays a crucial role in meeting these demands, improving production speed and quality.

Role of Intelligent Automation

Intelligent automation integrates AI, machine learning, and robotics, enhancing efficiency by automating tasks like cutting, welding, and coating. It reduces costs, minimizes human error, and ensures consistent quality, with systems like machine vision for quality control and predictive maintenance for machine uptime.

Automatic Manufacturing Machines

Automatic machines for three-piece can bodies include slitters for cutting materials, welders for forming cylinders, and coaters for protection. These systems can operate at speeds up to 500 cans per minute, handling steps like necking and flanging, ensuring precision for various can shapes and sizes.

Powder Coating for Weld Seams

After welding, powder coating is applied to weld seams to prevent corrosion, providing a thick, pore-free layer. This process, known as side seam striping, protects both internal and external surfaces, crucial for food safety and can integrity, unlike liquid coatings that may bubble.

Automatic Manufacturing Machines for Three-Piece Can Bodies: Technology and Process

● Slitters: Cut raw materials, such as tinplate, into precise blanks, ensuring accurate sizing for can bodies.

● Welders: Form the cylindrical can body by welding the edges of the blank, often using electric resistance welding for strong, seamless joints.

● Coaters and Dryers: Apply protective coatings to prevent corrosion and enhance durability, followed by drying to cure the coating.

● Formers: Shape the can body through processes like necking, flanging, beading, and seaming, ensuring the final form meets industry standards.

The can-body combined machine, which can perform multiple steps—such as slitting, necking, swelling, flanging, beading, and seaming—at speeds of up to 500 cans per minute.

Powder Coating for Three-Piece Can Weld Seams: Protection and Process

A critical step in three-piece can manufacturing is the treatment of weld seams, which are formed during the welding process to create the cylindrical can body. After welding, the weld seam is susceptible to corrosion due to surface oxidation, necessitating protective coating. Research suggests that powder coating, often referred to as “weld seam striping” or “side seam striping,” is employed to provide a thick, pore-free layer that protects against corrosion and chemical reactions. This is particularly important for cans holding sensitive materials like food, where contamination must be avoided.

The process involves applying powder coating to both the internal (ISS—inside side seam striping) and external (OSS—outside side seam striping) surfaces of the weld seam, followed by curing to ensure durability. Unlike liquid coatings, which may produce bubbles during drying, especially with thick layers, powder coatings ensure a smooth, uniform finish. This method is effective because it addresses challenges like spattering and surface roughness on the weld seam, which can occur with low-tin iron or chrome-plated iron, ensuring the coating layer remains intact during subsequent processes like flanging and necking.

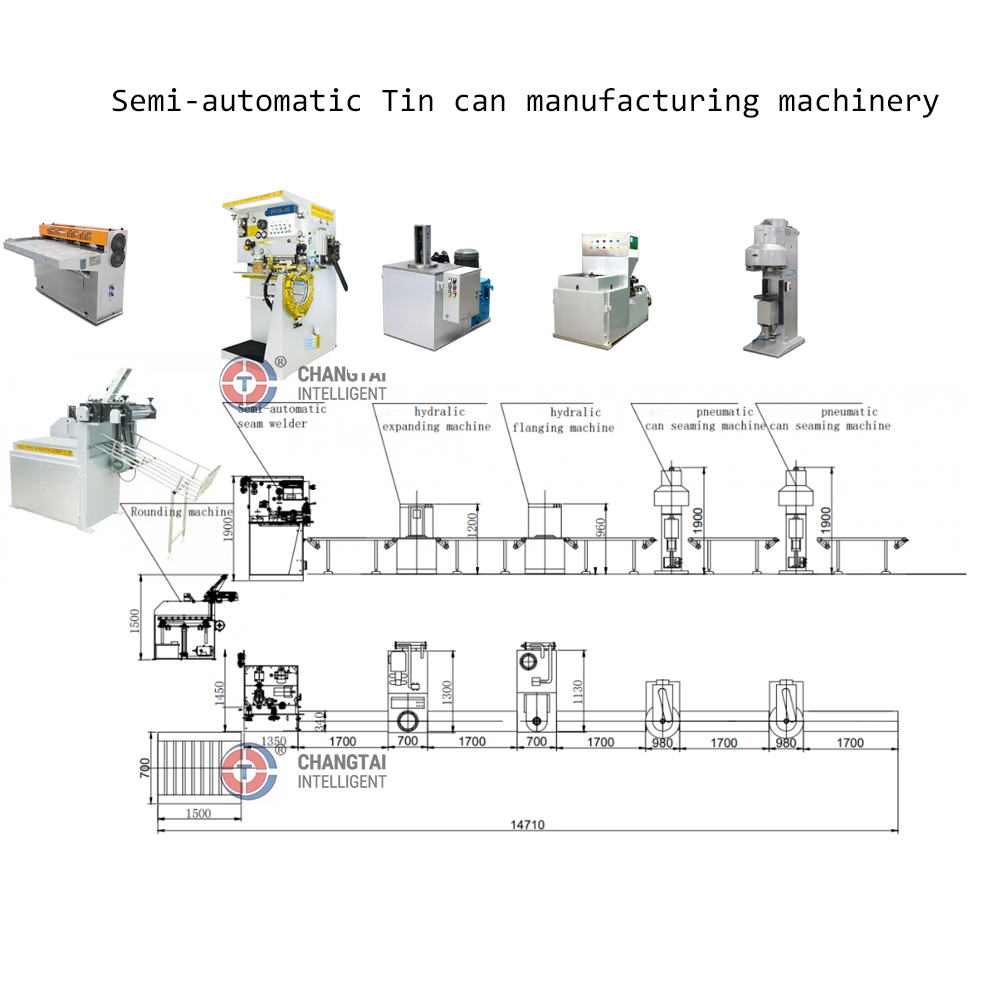

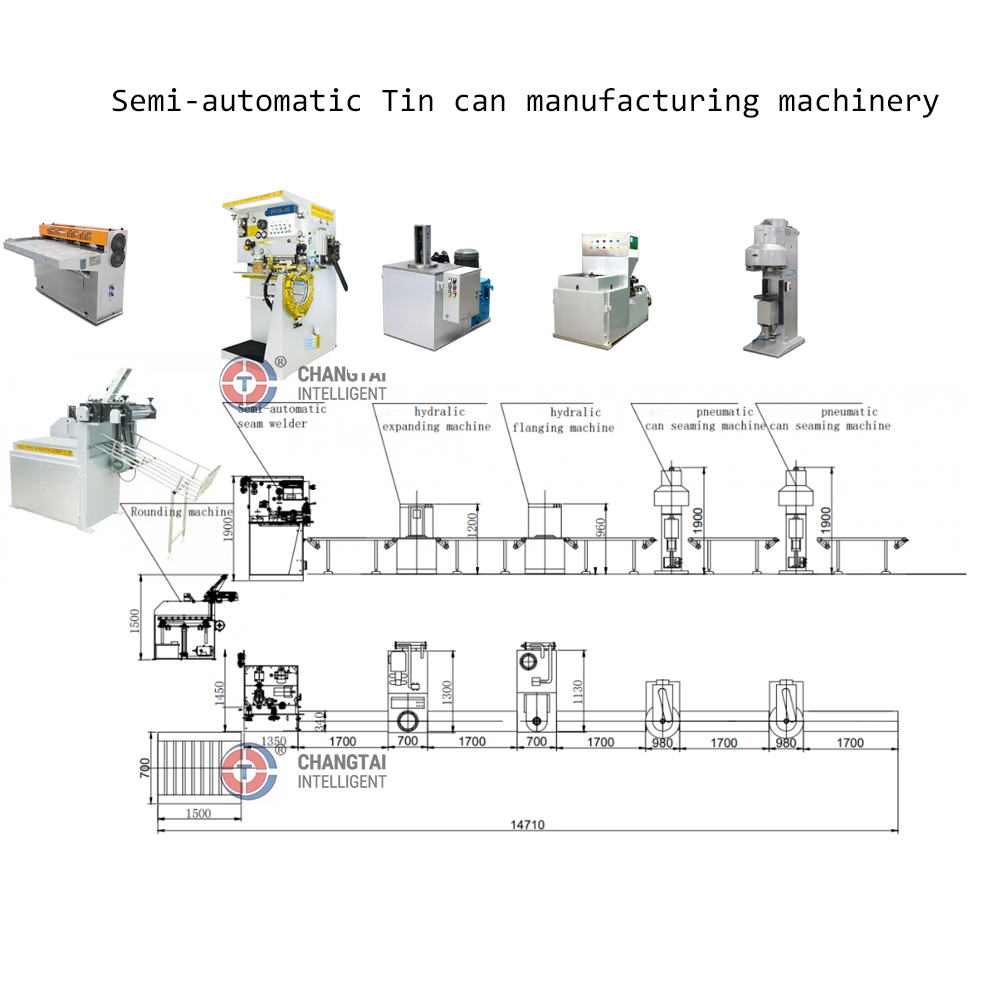

Chengdu Changtai Intelligent Equipment: Role and Offerings

Chengdu Changtai Intelligent Equipment, a Chinese national-grade manufacturer, is a leading provider of advanced machinery for the metal packaging industry, specializing in three-piece can manufacturing. The company offers a comprehensive range of fully automatic and semi-automatic can making machines, designed to meet the needs of global industries. Their product portfolio includes:

● Production lines for three-piece cans: Integrating multiple machines for seamless production, from slitting and welding to coating and curing.

● Automatic slitters: For cutting raw materials with high precision, ensuring accurate blanks for can bodies.

● Welders: For forming and welding can bodies, often incorporating electric resistance welding for strong seams.

● Coating and curing systems: For applying protective coatings, including powder coatings for weld seams, and drying to cure the coating.

● Combination systems: For integrating multiple production steps into a single, efficient process.

All parts of Chengdu Changtai’s machines are meticulously processed to ensure high precision, and each machine undergoes rigorous testing before delivery to guarantee optimal performance. Beyond manufacturing, the company provides comprehensive services, including installation, commissioning, skill training, machine repair, overhauls, troubleshooting, technology upgrades, and field service. This commitment to customer support ensures that clients can maintain their production lines with minimal downtime and maximum efficiency, serving industries like food packaging, chemical packaging, and medical packaging.

The three-piece can manufacturing industry benefits significantly from intelligent automation, which enhances efficiency and quality through advanced systems. Automatic manufacturing machines handle complex production processes with precision, while powder coating ensures weld seams are protected against corrosion, crucial for product safety. Chengdu Changtai Intelligent Equipment plays a pivotal role by providing advanced machinery and comprehensive support, meeting the diverse needs of global industries. Their commitment to innovation and quality positions them as a leader in the metal packaging market, ensuring that products are delivered safely and effectively.

The Changtai Intelligent Advantage: Precision, Quality, Global Support

- Uncompromising Quality: Every component within our machines is meticulously processed to achieve high precision and durability. Rigorous testing protocols are applied before delivery to guarantee optimal performance.

- Comprehensive Service & Support: We are your long-term partner, offering:

- Expert Installation & Commissioning: Ensuring your line starts up correctly and efficiently.

- Operator & Maintenance Training: Empowering your team to operate and maintain the equipment optimally.

- Global Technical Support: Rapid troubleshooting, machine repair, and overhauls to minimize downtime.

- Future-Proofing: Technology upgrades and kits conversion to keep your line current with evolving demands.

- Dedicated Field Service: On-site assistance whenever and wherever you need it.

Your Global Partner in Metal Packaging Solutions

Chengdu Changtai Intelligent Equipment is a leading force from China, supplying robust and intelligent three-piece can making machinery to the international metal packaging industry. We understand the unique challenges of producing cans for food, chemicals, pharmaceuticals, and other critical sectors, and we deliver the technology and support to overcome them.

Engineer a smarter, more efficient future for your three-piece can production.

Contact Chengdu Changtai Intelligent Equipment Today:

Let us equip you for excellence in metal packaging.

Post time:

Jun-10-2025