Steps in the Tray Packaging Process for Food Three-Piece Cans:

According to incomplete statistics, the total global production capacity for food cans is approximately 100 billion cans annually, with three-quarters utilizing the three-piece welded technology. The market share of three-piece cans varies significantly by region.

● North America: Out of a total of 27 billion food cans, over 18 billion are two-piece cans.

● Europe: 26 billion food cans use three-piece technology, while the growing two-piece segment accounts for only 7 billion cans.

● China: Food cans are almost exclusively three-piece, reaching a volume of 10 billion cans.

Can manufacturers choose three-piece technology for several reasons, the most important being its flexibility in accommodating varying customer requirements for can size and dimensions. Compared to large-scale producers of two-piece Draw & Wall Ironed (DWI) cans, three-piece manufacturers can more easily modify welding machines and related equipment to adapt to the production needs of cans with different heights and diameters.

For many years, both technologies have served their purposes. However, three-piece technology has continually pursued higher production efficiency and opportunities for lightweighting. Soudronic states that if customers are seeking lightweighting opportunities, three-piece cans can achieve it. A standard 500g three-piece can has a body thickness of 0.13mm and an end thickness of 0.17mm, weighing 33g. In contrast, a comparable DWI can weighs 38g. Nevertheless, it cannot be assumed that three-piece cans are lower cost without detailed analysis.

Reducing can weight is crucial for manufacturers: consumable costs, such as tinplate for bodies and ends, along with coatings, account for 75% of the total cost. However, the approach to weight reduction differs between three-piece and two-piece manufacturing: a lighter three-piece can might be cheaper but harder to handle, while the D&I process inherently involves thinning, providing a natural lightweighting characteristic.

High-Speed Welders Bring Three-Piece Production Close to Two-Piece Aluminum Speeds

Despite this, three-piece can efficiency has reached unprecedented levels. Two years ago, Soudronic launched a welding line claimed to produce 1,200 standard cans (300mm diameter, 407mm height) per minute. This speed approaches the average speed of 1,500 cans per minute for DWI food can lines.

The key to this speed lies in a copper wire feed system enabling welding speeds of up to 140 meters per minute – the speed at which the can body passes through the machine. Another innovation is the use of scoring technology in the body maker's former section for taller food cans. Two bodies of the same height are welded together, increasing speed by reducing the gap between cans on the machine. The twin cans are separated later down the line. Process control over welding, energy consumption, tinplate flow, and line management all contribute to increased line efficiency.

Shortly after its debut in 2014, dairy manufacturer Friesland Campina NV became the first customer to install such a line at its canning plant in Leeuwarden, Netherlands. As these were slightly smaller condensed milk cans, capacity could be increased to 1,600 cans per minute.

Subsequently, Heinz installed a similar high-speed line at its Kitt Green, UK, canning facility, which supplies one billion cans annually for various baked beans and pasta products.

Jakob Guyer, CEO of Soudronic AG, noted that Heinz evaluated both three-piece and DWI two-piece technologies very carefully for this new investment. Clearly, three-piece technology remains highly competitive in the market due to its high efficiency. Other customers worldwide, in Europe, Latin America, and Asia, have reached the same conclusion.

Werner Nussbaum of Soudronic detailed the line: "The entire line was designed by Soudronic AG, including the Ocsam TSN body blank cutter and the TPM-S-1 transfer system feeding the Soucan 2075 AF welder. Twin body welding using scoring technology is performed, with separation occurring on the Can-o-Mat combiner. The high-speed transfer system uses Mectra hardware and the Can-o-Mat system supplied by Soudronic subsidiary Cantec. Line control is an integral part of the Unicontrol system within the welder."

Compared to DWI lines, this three-piece line consumes less material, including production scrap. Furthermore, the investment for this high-speed three-piece line is significantly lower.

Three-Piece Production Efficiency Reaches Unprecedented Levels

Calculating with 3 shifts per day, 30 minutes cleaning per shift, one shift for maintenance every 20 days, and an overhaul every 35 days (excluding holidays), the total number of shifts per year reaches 940. Soudronic estimates that a line running at 1,200 cpm with 85% efficiency can achieve an annual output of 430 million cans.

Can manufacturers continue to invest in three-piece food cans globally. Four high-speed lines have been installed in the USA, two in Argentina, and one high-speed line for dairy cans in Peru. Customers in China have ordered high-speed lines for food and beverage cans.

In the USA, notably, Faribault Foods installed a Soudronic high-speed food can line in its new Minnesota plant. Faribault is owned by La Costeña, Mexico's largest food can producer.

Chinese Welder Makers Boost Competitiveness

In China, manufacturers of three-piece can welding equipment are increasing their production efficiency to enable customers to compete with the growing segment of two-piece aluminum beverage cans.

Chengdu Changtai Intelligent states that to enhance their competitiveness, three-piece can manufacturers must not only offer good quality and service but also lower production costs, a significant portion of which is tinplate. Consequently, thinner, harder tinplate is becoming increasingly popular.

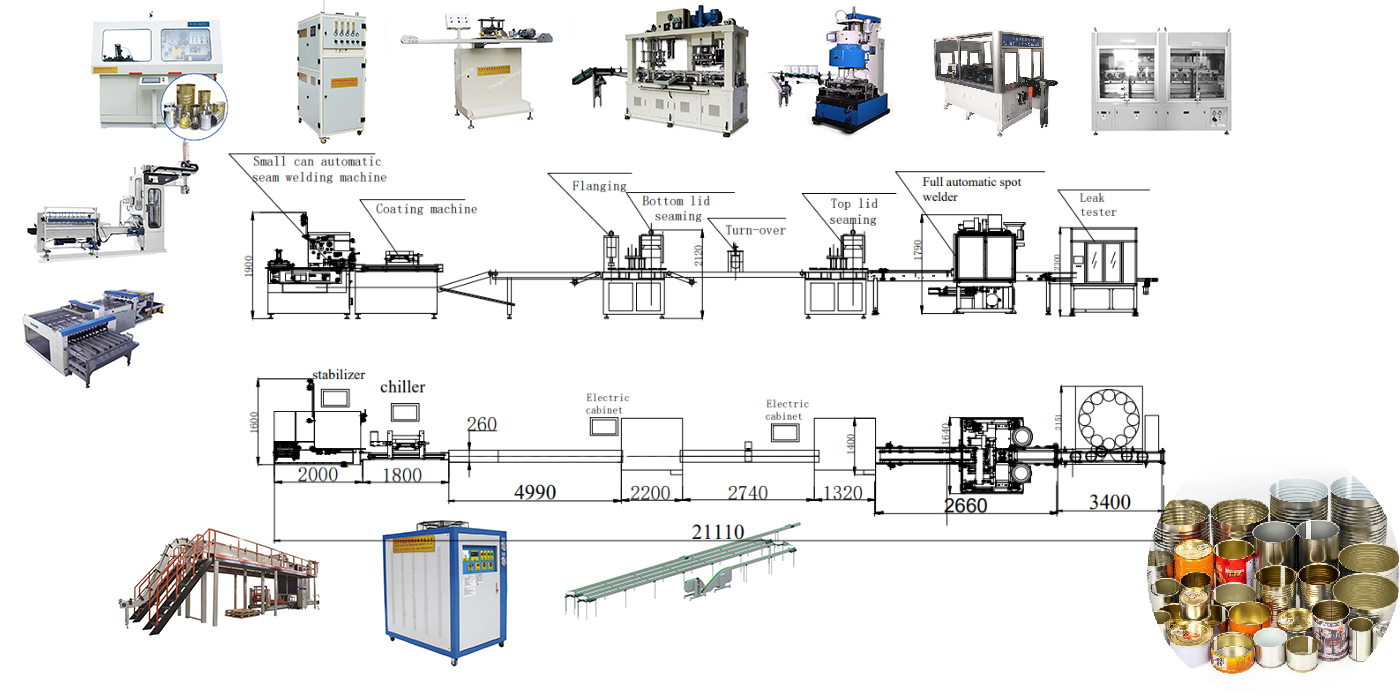

Chengdu Changtai Intelligent provides three-piece can making machinery, including semi-automatic and automatic bodymakers.

For your questions

We handle the price to a reasonable level and it can be adjust according to customer's needs. Then, the price will eventually based on request.

Of course yes! This will be our after-sales service.

Post time: Jun-25-2025