Innovation is the soul of packaging, and packaging is the charm of the product.

An outstanding easy-open lid packaging can not only effortlessly capture consumers’ attention but also enhance a brand’s competitive edge. As market demands diversify, cans of various sizes, unique shapes, and personalized designs are emerging endlessly, fully catering to consumers’ distinct needs. In the field of metal packaging, the future trends in can designs are drawing significant attention, with developments primarily reflected in the following areas:

1. Future Trends in Metal Packaging

◉ Innovation and Personalized Design

Innovation lies at the heart of design, especially in packaging. Exceptional easy-open lid cans can attract consumers’ attention and provide a competitive advantage for brands. In meeting the diverse needs of the market, personalized design plays a particularly vital role.

◉ The Rise of Special-Shaped Cans

While straight-walled cans—such as aerosol cans, beverage cans, and food cans—still dominate the market, special-shaped cans with distinctive personalities are steadily gaining consumer favor. This trend is especially prominent in Asian markets, where many consumers prefer uniquely shaped cans over monotonous straight-walled ones. This shift indicates that, in the future, special-shaped cans with personalized packaging will emerge as a market favorite.

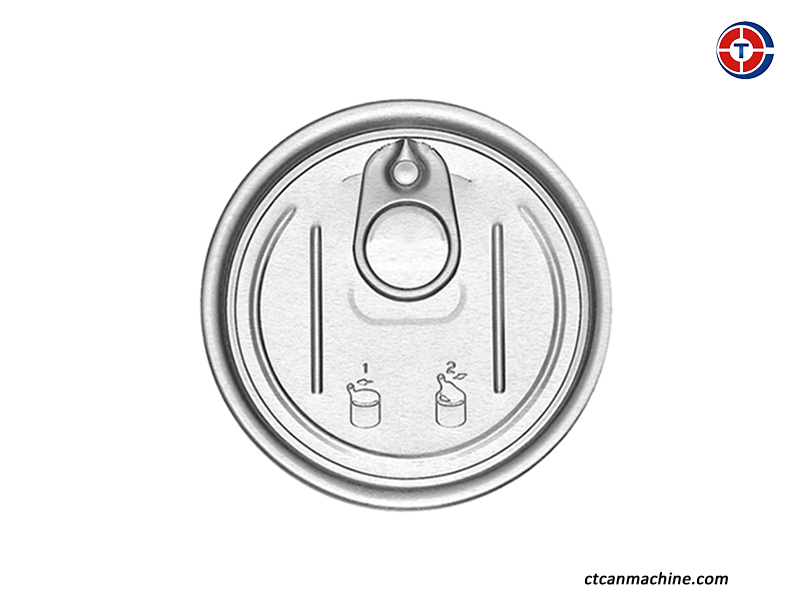

◉ Portable and Easy-to-Open Design

In Asia, stretch cans are frequently used for packaging fish and meat products. These cans are typically printed with UV ink and equipped with easy-open lids, allowing consumers to open them without additional tools. This simple and convenient design is increasingly popular, positioning portability and ease of opening as key considerations in packaging development.

◉ Transition from Three-Piece to Two-Piece Cans

Currently, canned beverages such as coffee and juice predominantly use three-piece can designs. However, as the packaging industry evolves, two-piece cans offer a cost advantage over three-piece cans in terms of materials. Reducing production costs is critical for the long-term success of businesses, making the shift from three-piece to two-piece cans an emerging industry trend.

◉ Food Safety and Printing Technology

With rising living standards, food safety has become a growing concern. The migration of harmful substances in metal packaging has emerged as a significant safety risk. Issues such as heavy metals, organic volatiles, and solvent residues in the ink printing process urgently need resolution to ensure packaging safety. Meanwhile, the flexibility of digital printing allows brand owners to better address demands for identifiable and personalized packaging. This technology brings new opportunities to the metal packaging sector, enabling more adaptable responses to specific customer needs while improving the quality and efficiency of post-printing processes, such as glazing and other specialized techniques.

China leading provider of 3 piece Tin Can Making Machine and Aerosol Can Making Machine, Changtai Intelligent Equipment Co., Ltd. is an experienced Can Making Machine factory.Including parting, shaping, necking, flanging, beading and seaming,Our can making systems feature high-level modularity and process capability and are suitable for a wide range of applications, With fast, simple retooling, they combine extremely high productivity with top product quality, while offering high safety levels and effective protection for operators.

Post time: May-30-2025