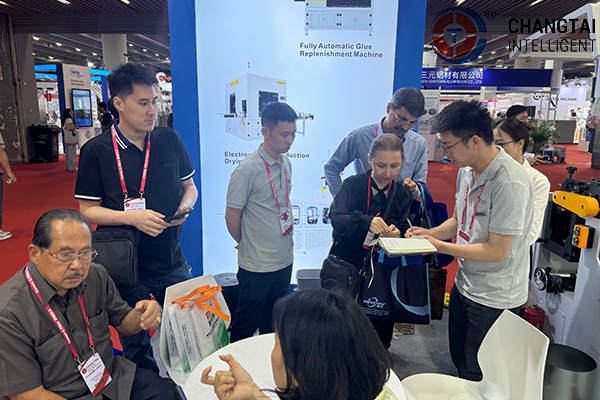

AI-Powered Innovation in Can Manufacturing: Changtai Intelligent’s attention to Global Leaders

The manufacturing sector is experiencing a profound shift as artificial intelligence (AI) reshapes production processes worldwide.

From enhancing efficiency to improving product quality, AI is setting new standards in operational excellence across industries,such as in our can manufacturing industry. And companies in the world are integrating AI into their workflows, Chengdu Changtai Can Manufacture Equipment (Changtai Intelligent) is following up, we committedto research and adopt these innovative ideas to elevate its own can-making processes.

Global Examples of AI in Can Manufacturing

Several pioneering companies have already applied the transformative potential of AI in production environments similar to can manufacturing.

These examples provide a roadmap for Changtai Intelligent as it seeks to enhance its product offerings:

Predictive Maintenance: Leading automobile manufacturers, as highlighted in industry reports, use AI to predict equipment failures before they occur. By analyzing data from sensors and employing digital twins—virtual replicas of physical systems—these companies can schedule maintenance during off-peak hours, reducing downtime and costs. This approach is highly applicable to can manufacturing, where continuous production is critical.

Quality Control: AI-powered computer vision systems are revolutionizing quality assurance. Companies in various manufacturing sectors deploy machine learning algorithms to analyze real-time images of products, detecting defects with greater precision than human inspectors. For can production, this technology could ensure flawless seams and surfaces, a key focus for Changtai Intelligent’s automatic canbody welders.

Mass Customization: AI enables manufacturers to adapt quickly to customer preferences without sacrificing efficiency. By integrating AI into design and production processes, companies can respond to real-time feedback, tailoring products to meet specific demands. This flexibility could allow Changtai Intelligent to offer customized can-making solutions while maintaining high throughput.

Warehouse Management: AI-driven automated guided vehicles (AGVs) are streamlining logistics operations. For instance, BMW utilizes AGVs to transport materials and finished goods within its facilities, improving inventory tracking and operational flow. Changtai Intelligent could adopt similar systems to optimize the movement of raw materials and finished cans in its production lines.

Robotic Process Automation (RPA): AI is also automating repetitive administrative tasks. By applying machine learning to processes like purchase orders, invoicing, and quality reporting, manufacturers reduce errors and free up resources. This could enhance the efficiency of Changtai Intelligent’s semi-automatic backward seam welding machine operations [Source: Automation Industry Studies].

Changtai Intelligent’s Vision for AI Integration

Changtai Intelligent specializes in the research, development, production, and marketing of automatic and semi-automatic can-making equipment, including its renowned automatic canbody welders and semi-automatic backward seam welding machines (ctcanmachine.com). Recognizing the global trend toward AI-driven manufacturing, the company is determined to apply these technologies to improve the intelligence and efficiency of its products.

Changtai Intelligent plans to study inspiration from these international case studies, tailoring AI solutions to its specific needs. Key areas of focus include:

Enhanced Efficiency: By adopting predictive maintenance, Changtai aims to minimize equipment downtime and optimize production schedules, ensuring seamless operation of its can-making lines.

Superior Quality: Implementing AI-based computer vision will enable the company to maintain the highest standards of precision and consistency in its can manufacturing processes.

Operational Streamlining: Through AI-powered warehouse management and RPA, Changtai intends to automate logistics and administrative tasks, reducing manual effort and boosting overall productivity.

A Commitment to Innovation

Changtai Intelligence’s proactive and enterprising spirit reflects its determination to maintain a leading position in the highly competitive can-making industry.

By researching and adapting to the creative applications of artificial intelligence demonstrated by global leaders, the company is prepared to enhance its technological capabilities and provide customers with smarter and more efficient solutions. As artificial intelligence continues to redefine manufacturing, Changtai Intelligence will play a leading role in introducing these advancements into the can-making industry, solidifying its position as an innovator in this field.

Post time: May-05-2025